ERW API WELDED TUBE MILL LINE

HG φ165-508(130x130-400x400)

Sinoform independently developed API ERW Tube Mill with the latest FFX FF forming technology and adopt Germany COPRA forming software according to the internationally accepted oil and gas pipeline transportation standard API SPEC 5L&5CT ASTM,Complete line easily operated and stable running performance,also the complete tube mill line meet a high level automation.

Sinoform independently developed API ERW Tube Mill with the latest FFX FF forming technology according to the internationally accepted oil and gas pipeline transportation standard API SPEC 5L&5CT ASTM, which can produce high-grade pipe materials ie; X42 to X120, with pipe diameters from6" to 24"φ165-610mm, thickness 4-20mm, line speed max up to 30m/min, High Frequency welder power: 1000-1700kw, Annealing: 3000kw, 1.0kHZ.

Our customized machines are also can be used for oil and gas pipeline transportation

FLOW CHART OF ERW TUBE MILL

LINE COMPONENTS:

-

UNCOILER AND ENTRY SECTION

-

ACCUMULATOR

-

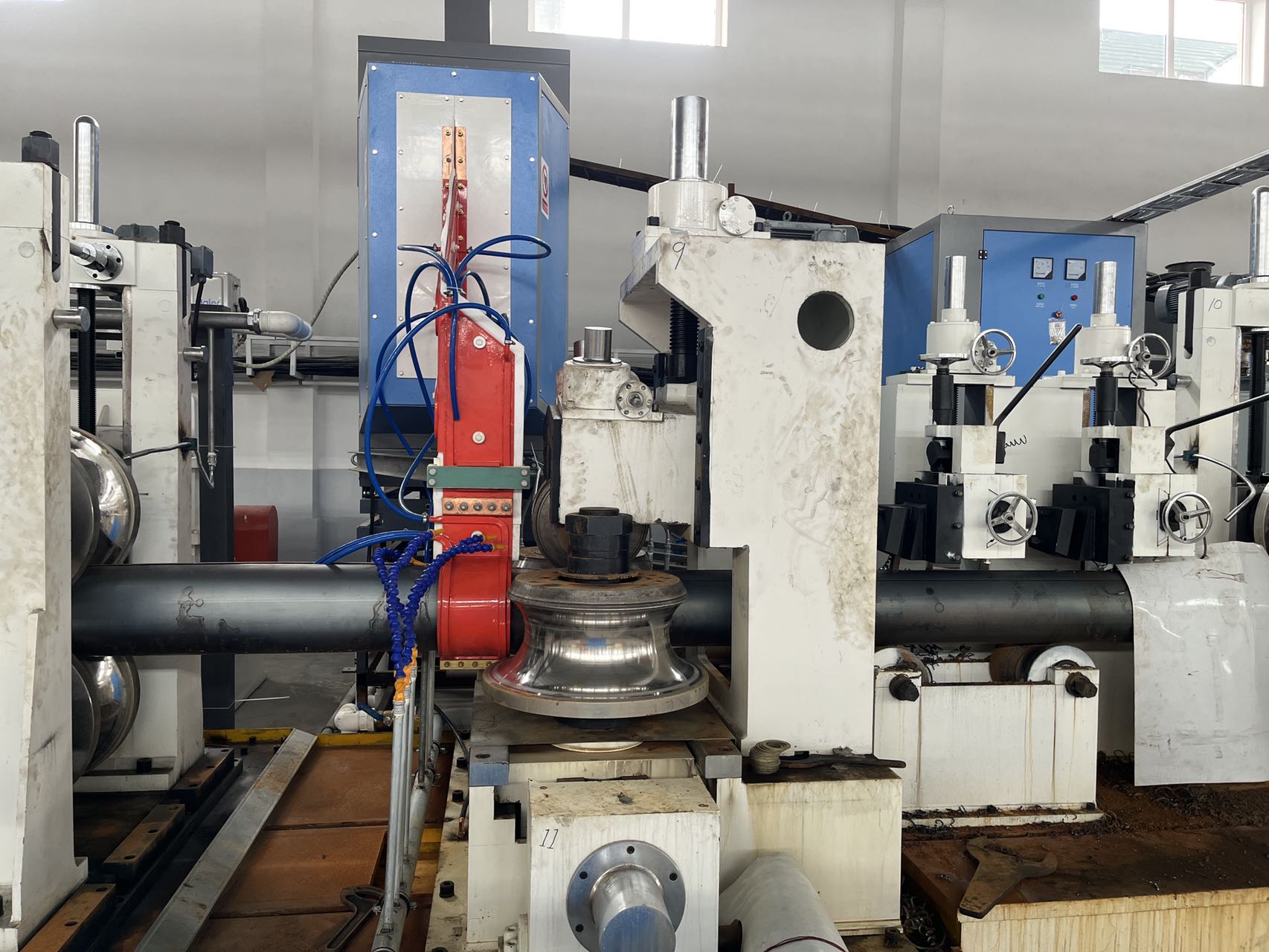

FORMING SECTION

-

HF WELDER

-

CUT-OFF SAW

-

SIZING SECTION

VIDEO:

TECHNICAL DATA:

| Machine Model | Production Range (mm) |

Wall Thickness Of Square Pipe |

Milling Speed (m/min) |

High Frequency Power |

| HG16 | ∅8~∅25mm □6x6~20x20 | δ0.3~1.0mm □δ≤0.8mm | 20~120 | 100KW |

| HG25 | ∅8~∅32mm □6x6~25x25 | δ0.4~1.3mm □δ≤1.0mm | 20~120 | 100KW |

| HG32 | ∅13~∅50.8mm □10x10~40x40 | δ0.6~2.0mm □δ≤1.5mm | 20~120 | 150KW |

| HG50 | ∅19~∅63.5mm □15x15~50x50 | δ0.8~2.5mm □δ≤2.0mm | 20~100 | 200KW |

| HG60 | ∅19~∅76mm □15x15~60x60 | δ1.0~3.0mm □δ≤2.5mm | 20~90 | 250KW |

| HG76 | ∅25~∅90mm □20x20~70x70 | δ1.5~4.0mm □δ≤3.5mm | 20~90 | 300KW |

| HG90 | ∅30/48~∅115mm □25x25~90x90 | δ1.5~4.5mm □δ≤3.5mm | 20~60 | 300KW |

| HG115 | ∅32/48~∅127mm □25x25~100x100 | δ2.0~5.0mm □δ≤4.0mm | 15~60 | 400KW |

| HG165 | ∅76~∅165mm □60x60~130x130 | δ2.0~6.0mm □δ≤5.0mm | 15~50 | 500KW |

| HG219 | ∅114~∅219mm □90x90~170x170 | δ3.0~8.0mm □δ≤6.0mm | 15~40 | 600KW |

| HG273 | ∅114~∅273mm □90x90~200x200 | δ4.0~12.0mm □δ≤9.0mm | 10~30 | 800KW |

| HG325 | ∅165~∅325mm □130x130~250x250 | δ4.0~12.0mm □δ≤10.0mm | 10~30 | 800KW |

| HG426 | ∅165~∅426mm □130x130~300x300 | δ5.0~16.0mm □δ≤14.0mm | 10~30 | 1000KW |

| HG508 | ∅219~∅508mm □170x170~400x400 | δ6.0~16.0mm □δ≤15.0mm | 10~25 | 1000KW |

Any query please feel free to contact us

SINOFORM team will provide you complete technical solution