COLD FLYING CUTTING SAW

As an indispensable part of the pipe cutting at the end of the welded pipe production line, the cold saw plays a decisive role in the quality of the finished pipe. Sinoform has accumulated 20 years of experience in the welded pipe industry, and our pipe cold cutting saw has reached advanced international standards.

INTRODUCTION:

SINOFORM HG series have 2 types of flying saws

The metal is cut off by rapidly rotated circular saw at room

temperature, the cut off end face is level and smooth like a mirror.

Very small internal and external burr, flat and smooth millingsurface,

no need follow-up processing, saving the process and raw materials.

Commonly known as computer flying saw, also known as friction saw. High-speed cut-off accompanied by high temperature, sparks, cutting the end was purple, more flash burr.Large internal and external burr need flat-chamfering and other follow-up, increase human energy and raw materials consumption costs.

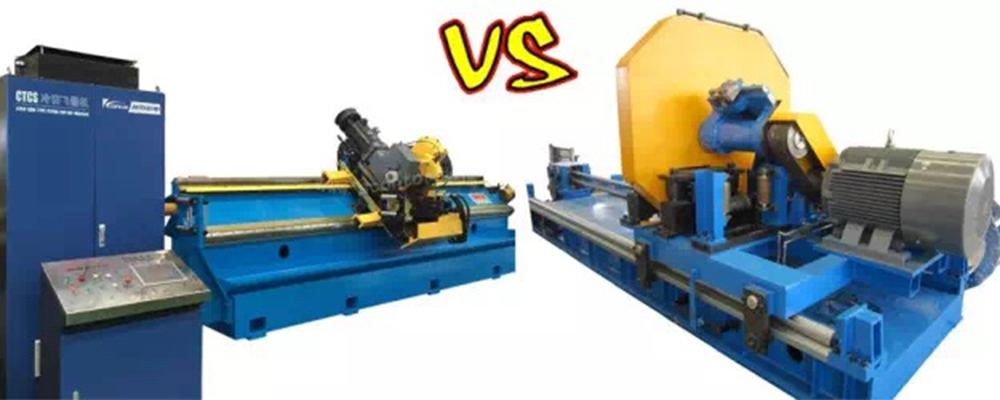

HOT FRICTION SAW VS COLD CUT OFF SAW:

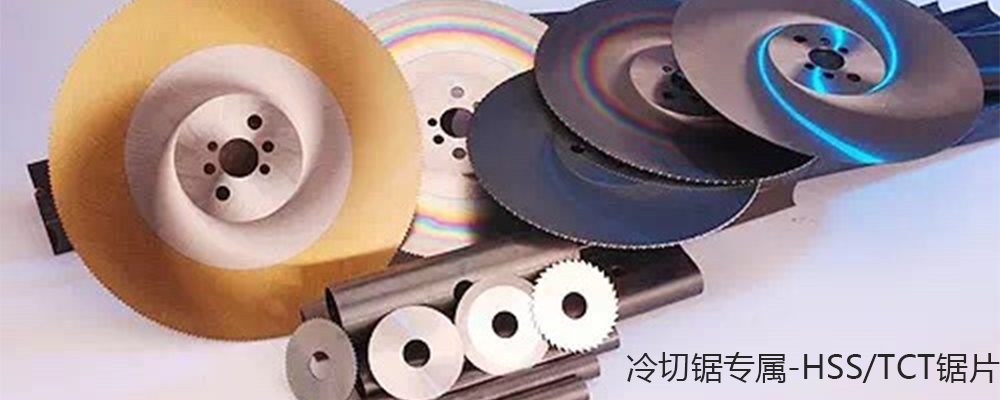

SAWING METHOD

Cold cut off Saw: Slow rotation by HSS steel saw, milling cut the pipe, it can attend burr-free and noise-free. The sawing process produces very little heat, the saw blade has little pressure on the pipe and it won’t cause the deform of pipe wall.

Hot friction saw: flying saw use high-speed rotation of tungsten steel saw, the heat generated by contact with the pipe to make it break down,actually it is blown. Surface shows high fuel marks and it cause a lot of heat, the saw blade bring a lot of pressure on the steel pipe which resulting in quality defects like tube wall nozzle deformation.

CUTTING QUALITY

Cold cut off Saw: very small internal and external burr, flat and smooth milling surface, no need follow-up processing, saving the process and raw materials

Hot friction saw: large internal and external burr,need flat-chamfering and other follow-up, increase human energy and raw materials consumption costs

LENGTH PRECISION

Cold cut off Saw: fixed length ± 2.0mm, the same specification repeatability ± 0.5mm no need second length, saving process and raw materials

Hot friction saw: ± 2.5mm, most need offline length sub-cut, Waste human energy and raw materials

SAFETY

Cold cut-off saw:max linear velocity 200m/min,Even if the accidental explosion of the saw blade will not cause damage to the personnel and equipment

Hot friction saw:max linear velocity 80m/min,If the accidental burst of the saw blade will cause damage to the personnel and equipment

VIDEO:

TECHNICAL DATA:

| Max. Dia.(mm) | Model | Wall Thickness (mm) | Drag Power (KW) | Feed Power (KW) | Max. Speed(mm/min) |

| Max.Φ25 | HGQ-25 | 1.5 | 7.5 | 1.3 | 120 |

| Max.Φ40 | HGQ-40 | 2.3 | 11 | 1.8 | 120 |

| Max.Φ63.5 | HGQ-63q | 2 | 11 | 1.8 | 120 |

| HGQ-63 | 3 | 11 | 1.8 | 120 | |

| Max.Φ76.2 | HGQ-76 | 3.2 | 11 | 2.9 | 80 |

| Max.Φ90 | HGQ-90q | 4 | 15 | 2.9 | 70 |

| Max.Φ90 | HGQ-90 | 4.5 | 15 | 2.9 | 70 |

| Max.Φ101.6 | HGQ-100 | 4.5 | 15 | 2.9 | |

| Max.Φ114.3 | HGQ-114 | 4 | 15 | ||

| HGQ-114z | 5 | 15 | 4.4 | 50 | |

| Max.Φ140 | HGQ-140 | 6 | 22 | 5.5 | 50 |

| Max.Φ168.3 | HGQ-168 | 8 | 22 | 5.5 | 50 |

Any query please feel free to contact us

SINOFORM team will provide you complete technical solution